YOUR GLOBAL PARTNER IN MANUFACTURING POLYMER SOLUTIONS

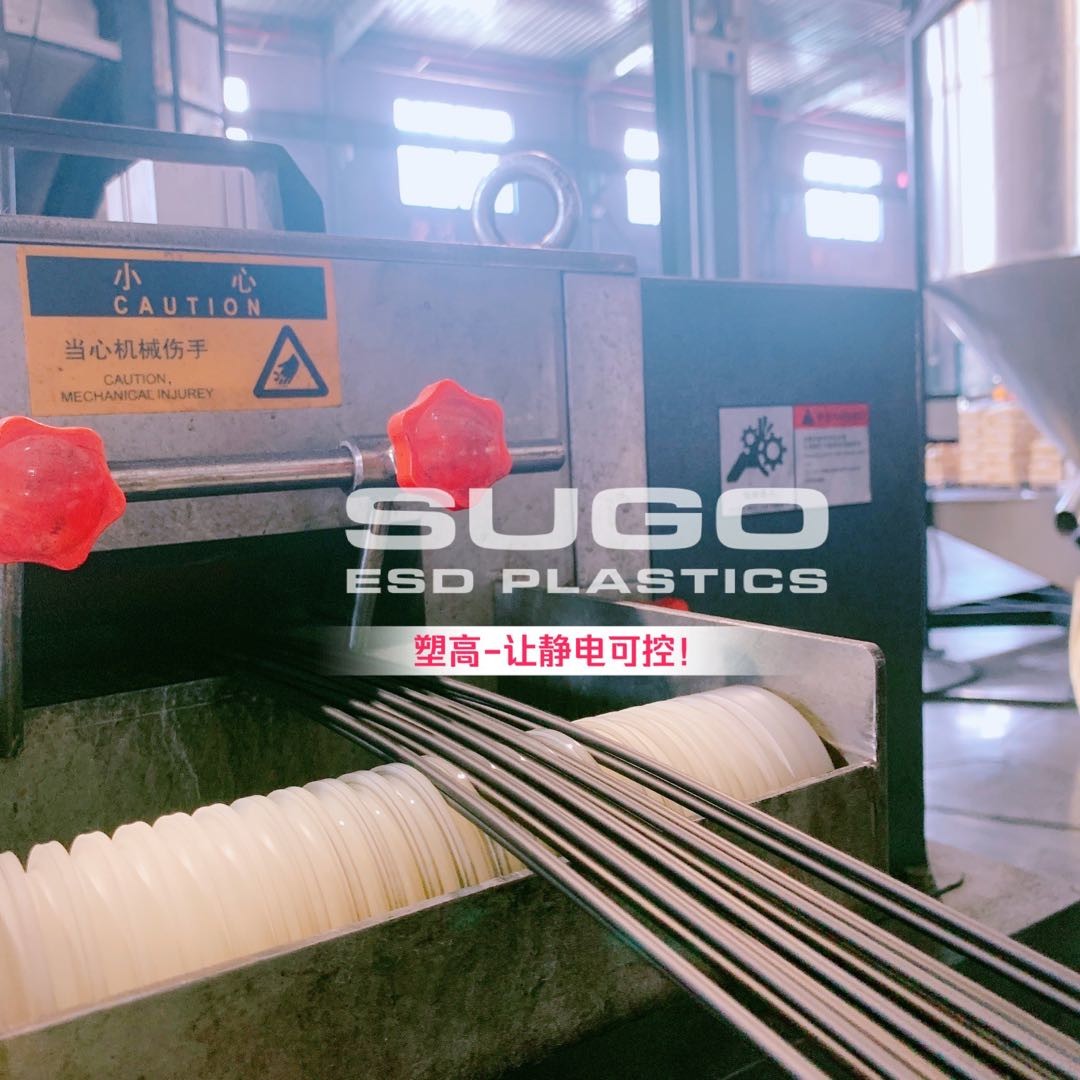

Sugo ESD Plastics is a globally recognized designer and manufacturer of custom Conductive masterbatch,

anti static Master Batch, engineered compounds and performance technologies. Our business is built around

delivering Performance, Solutions and Trust through close collaboration with customers seeking to optimize

their polymer products. All of our products are backed by complete technical support that ensures quality,

reliability, and value. Sugo ESD Plastics operates manufacturing plants and maintains sales offices based

in China. Central research and development facilities and headquarters are located in Ganzhou City of China.

ESD compound series include:

ESD ENGEERING PLASTICS COMPOUND:

PA, PC, PC+ABS ALLOY, POM, PBT, PPO/PPE,

ESD SPECIAL PLASTICS COMPOUND:

PPS, PEI, PES, PSU,PEEK, LCP

ESD GENERAL PLASTICS COMPOUND:

ABS, PP, PS, PE

ESD THERMOPLASTIC ELASTOMER:

TPE, TPU, TPR, PVC, TPV

ESD MASTERBATCHES/ADDITIVES

CONDUCTIVE MASTERBATCH

OUR ADVANTAGES:

Reduce your cost.

Increase your productivity.

Full range of ESD plastics compound.

Widely applications.

Strong technical strength andstrict quality test system ensure the provision of highly reliable products.

OUR SERVICES:

Before sale

Fully understand customer’s individual product need, quality standards and manufacture requirements. According to above requirements, develop the most suitable ESD material for our customers.

During sale

Provide the most scientific and professional operation advice, including mold design and development, processing introduction and on-site technical service and training.

After sale

Provide customer solution in a high speed and efficiency aiming to the problem that customers encounter after using our products. Additionally, conduct the periodic customer satisfaction survey to understand customer need. Gain customer’s full satisfaction and trust through our service and cooperation and realize win-win market position.

![]()

![]()

![]()