Corrosion Less Antistatic Masterbatch , ESD Protection Masterbatch Good Viscosity

Product Details:

| Place of Origin: | DONGGUAN, China |

| Brand Name: | SUGO |

| Certification: | ROHS, REACH |

| Model Number: | TH3045 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 200 kgs |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kg per bag, paper bag with inner PE layer |

| Delivery Time: | 3-7 days |

| Payment Terms: | 100% T/T before shipment, or LC at sight |

| Supply Ability: | 1000TONS/M |

|

Detail Information |

|||

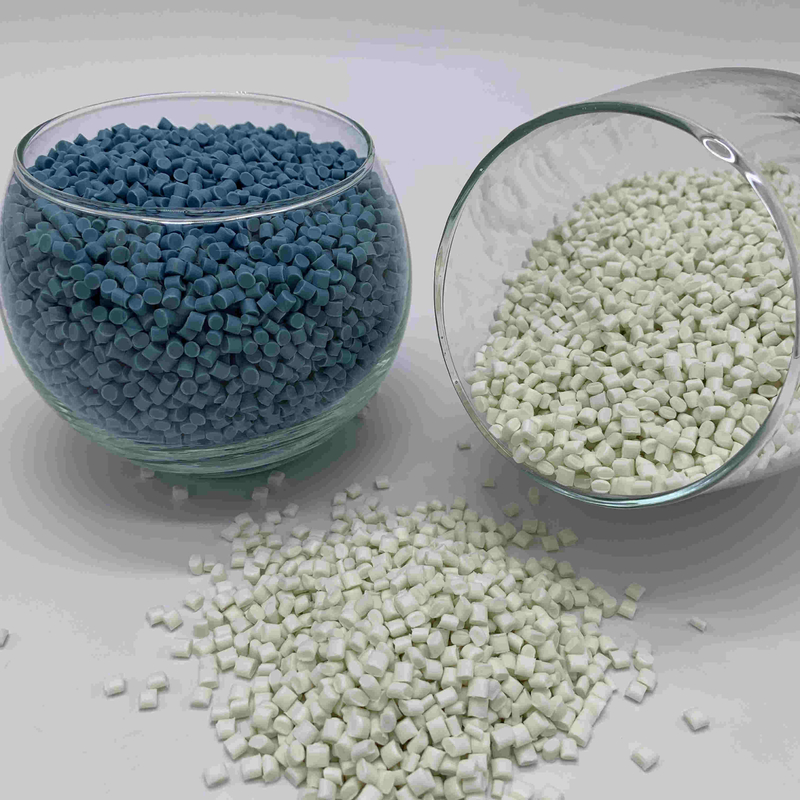

| Advantage: | Good Viscosity | Form: | Cylindrical Pellet |

|---|---|---|---|

| Usage: | ESD Application | Surface Resistivity: | 10E3-10E9 |

| Function: | Eletrically Conductive Or ESD Protection | Standard: | Environmental Friendly |

| Payment Term: | T/T, L/C | Appearance: | Pellets |

| High Light: | conductive black masterbatch,conductive esd training material,Corrosion Less Antistatic Masterbatch |

||

Product Description

Corrosion Less Antistatic Masterbatch , PP Masterbatch Good Viscosity ESD Protection

Product Description

Antistatic additives used in plastics are of two categories. One is migrating type in which the antistatic effect is temporary. Some of the applications require a permanent long lasting antistatic performance. The polymeric permanent antistatic type additives exhibits excellent antistatic performance right after the product comes out of the machine till the end of life. The permanent antistatic material can be used for extrusion, injection molding and coating applications. Loading of 5 to 20% can provide the surface resistivity of 10E9 to 10E12 range in humidity range from 20% to 50%.

Main Features

Antistatic Master Batch, an internal antistatic agent acts in two ways:

- Builds up conductive path to bring charged particles into contact.

- As a lubricant or mould- release agent in the post extrusion process.

Using Anti Static Masterbatch will reduce or even eliminate the problems caused by high surface resistivity These problems Include:

- Increase handling problems during transport, storage and packing.

- Dust contamination, affecting both, appearance and performance of end products.

- Risk of electrical shocks to employees working at the machines

- Risk of electrical discharge causing fire or explosion

| SUGO’s ESD compounds are formulated by combining carbon fiber,carbon powder, non-carbon based homogeneous materials and thermoplastic resins. These compounds meet the needs of many industries where permanent reduction of electrostatic hazards is required, our materials are: | ||||

| ESD Series | ||||

| TYPE | Material | Grade | Processing method | Application |

| ESD ENGEERING PLASTICS COMPOUND: | PA | ·Conductive 102x 105 ohms/square · Static dissipative 106x 109 ohms/square · Antistatic 108x 1011 ohms/square | Injection | Rod, sheet, IC trays, housings, electronic components, etc |

| PC | ||||

| PC/ABS | ||||

| PBT | ||||

| POM | ||||

| PPO/PPE | ||||

| ESD SPECIAL PLASTICS COMPOUND: | PPS | electrical & eletronics components, Auto parts, medical equipment, etc | ||

| PEI | ||||

| PES | ||||

| PSU | ||||

| PEEK | ||||

| LCP | ||||

| ESD GENERAL PLASTICS COMPOUND | ABS | Injection, extrusion | Rod, sheet, film, tube, etc | |

| PP | ||||

| PS | ||||

| PE | Injection, extrusion, blowing | |||

| ESD THERMOPLASTIC ELASTOMER | TPE | Injection, extrusion | Auto parts, extruded products, eletrical & eletronics components, traffic equipment | |

| TPR | ||||

| TPU | ||||

| TPV | ||||