Electrical Blue Antistatic Conductive Masterbatch ESD Protection Application

Product Details:

| Place of Origin: | DONGGUAN, China |

| Brand Name: | SUGO |

| Certification: | ROHS, REACH |

| Model Number: | TH3045 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 200 kgs |

|---|---|

| Price: | Negotiable |

| Packaging Details: | 25kg per bag, paper bag with inner PE layer |

| Delivery Time: | 3-7 days |

| Payment Terms: | 100% T/T before shipment, or LC at sight |

| Supply Ability: | 1000TONS/M |

|

Detail Information |

|||

| Color: | Customized | Carrier: | Pe,Pet,Pa,Pp,Abs, Etc |

|---|---|---|---|

| Application: | Sheet | Surface Resistivity: | 10E3-10E9 |

| Function: | Eletrically Conductive Or ESD Protection | Material: | Antistatic |

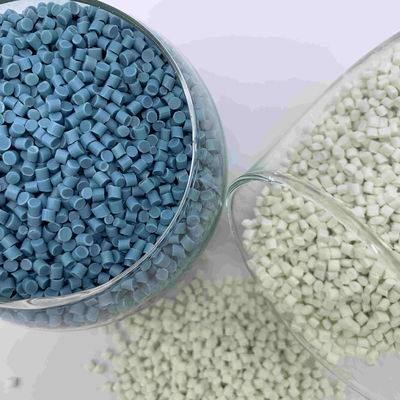

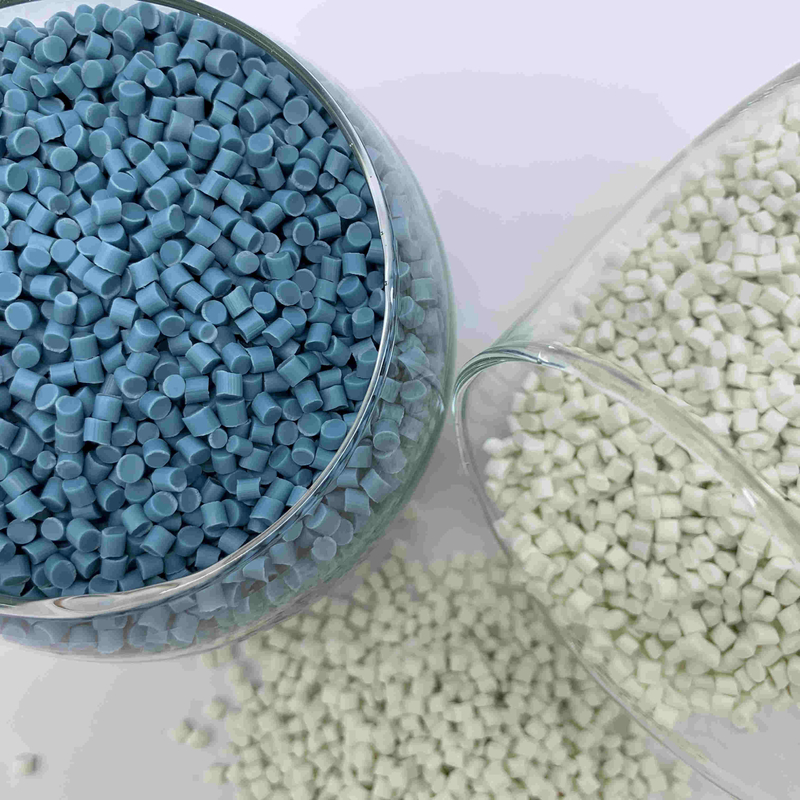

| Payment Term: | T/T, L/C | Appearance: | Pellets |

| High Light: | conductive black masterbatch,conductive esd bag material,Blue Antistatic Conductive Masterbatch |

||

Product Description

Electrical Blue Antistatic Conductive Masterbatch ESD Protection Application

Product Description

Anti static masterbatches are for commodity plastics. Commodity plastics by nature possess an electrical insulating property which gives them the potential to built-up high static charge on their surfaces due to friction caused by dry air moving over them or movement against other the surfaces.

The static charge may cause several processing problems such as difficulty in winding of films or melt-spun fibers, agglomeration of powders during transport, adhesion of films during processing, etc. Such undesirable effects of static charge build-up can be avoided by using masterbatches containing antistatic agents. The most commonly used are those compounded internally with the polymer and those applied topically.

Features:

- Reduces Surface Resistivity of Plastics

- Reduces Dust Pickup

- Reduces Static charge built-up on plastics

- Protectiveness electronic cards

Applications

- PE Blown Films.

- PP Cast Films.

- PS Sheets & Disposables.

- PE Bubble Film Sheets.

- Injection Molded Parts.

| SUGO’s ESD compounds are formulated by combining carbon fiber,carbon powder, non-carbon based homogeneous materials and thermoplastic resins. These compounds meet the needs of many industries where permanent reduction of electrostatic hazards is required, our materials are: | ||||

| ESD Series | ||||

| TYPE | Material | Grade | Processing method | Application |

| ESD ENGEERING PLASTICS COMPOUND: | PA | ·Conductive 102x 105 ohms/square · Static dissipative 106x 109 ohms/square · Antistatic 108x 1011 ohms/square | Injection | Rod, sheet, IC trays, housings, electronic components, etc |

| PC | ||||

| PC/ABS | ||||

| PBT | ||||

| POM | ||||

| PPO/PPE | ||||

| ESD SPECIAL PLASTICS COMPOUND: | PPS | electrical & eletronics components, Auto parts, medical equipment, etc | ||

| PEI | ||||

| PES | ||||

| PSU | ||||

| PEEK | ||||

| LCP | ||||

| ESD GENERAL PLASTICS COMPOUND | ABS | Injection, extrusion | Rod, sheet, film, tube, etc | |

| PP | ||||

| PS | ||||

| PE | Injection, extrusion, blowing | |||

| ESD THERMOPLASTIC ELASTOMER | TPE | Injection, extrusion | Auto parts, extruded products, eletrical & eletronics components, traffic equipment | |

| TPR | ||||

| TPU | ||||

| TPV | ||||